FABRICATION

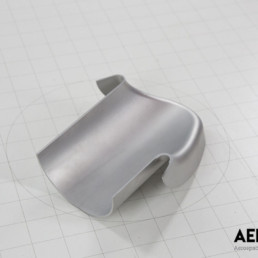

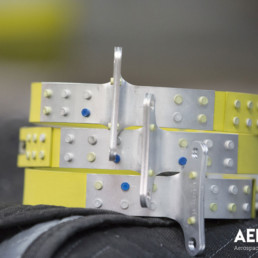

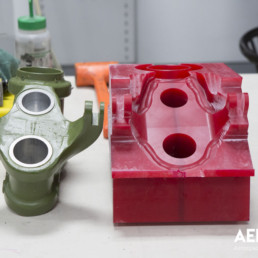

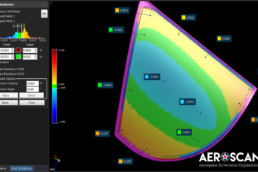

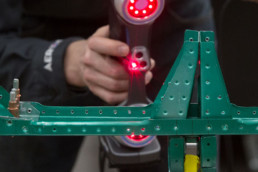

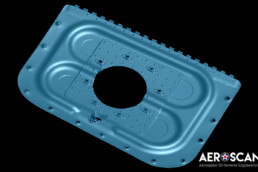

The Aeroscan’s fabrication team specializes in the use of traditional and state-of-the-art methods to manufacture and produce aircraft parts. Our adherence to the FAA-PMA Quality System, range of capabilities, and exacting detail are evident in the finished product. We have built this reputation by fabricating parts for the legacy and warbird markets, but can also produce approved components for modern aircraft and even other industries. Whether it’s stretching a leading edge skin, spot-welding an assembly, machining a main landing gear casting, or producing a formed sheet metal part, customers benefit from working with a premier production team who have access to an extensive collection of resources, equipment and tools.

Shop Highlights

- FAA-PMA quality system

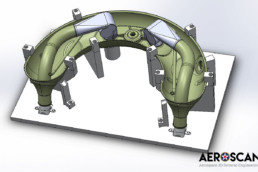

- Solidworks CAD design software

- BOBCAD/ CAM machining software

- Full range of manufacturing equipment

- On staff, aircraft part experienced fabricators CAD designers & machinists

Internal Process capabilities

- CNC machining

- CNC turning

- CNC router cutting

- Stretch forming

- Rubber form pressing

- Drop hammer forming

- Aluminum heat treatment

- Aluminum spot welding

- Riveting

- Phenolic forming

- 12’ sheet metal rolling