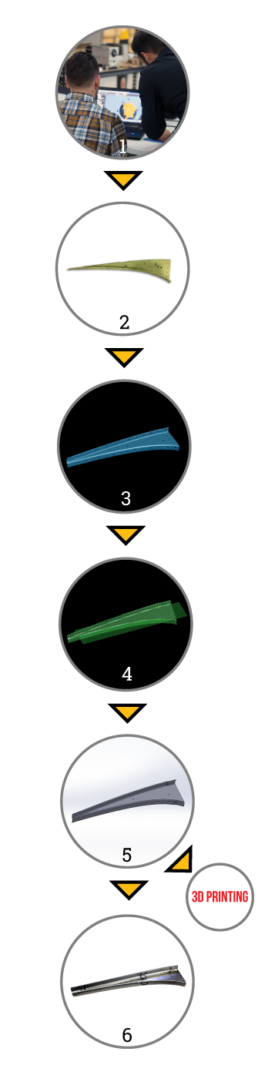

PROCESS

Objects are typically 3D scanned for two purposes: Reverse engineering or Inspection. Depending on what your goals are those efforts require different workflows. Use this page to educate on what the “process” is and how we can help you through it.

Typical Reverse

Engineering Process

Step 1: Discuss the application

Contact Aeroscan to discuss your project. Aeroscan will verify that 3D scanning can be applied and benefit your objective. We will also determine which of the following steps are required to meet your goals. For example, you may have the ability to model in CAD or fabricate/ manufacture the part yourself. We can provide whatever deliverables at any step in the process so that you have data that works for you.

Step 2: Define articles/ subjects to scan

Once the deliverables are defined, the subject to be reverse engineered is supplied by shipping or Aeroscan arriving at your location.

Step 3: 3D Laser Scanning

The part is scanned and instantaneously developed as a 3D mesh model. Aeroscan can provide 3D laser scanning for parts that will fit in your hand up to an entire aircraft.

Step 4: Post-Processing

Post processing refers to the effort of “cleaning” and repairing the scan data. Often the scan has unwanted content or areas that need more detail. This step also allows us to attach “entities” or reference that will be exported for the next phase of 3D modeling.

Step 5: CAD Modeling

CAD modeling is where the part is perfected by using the scan reference. By 3D scanning, This step is where time savings are truly captured. 3D scanning not only cuts the time down in measuring the part but it provides 3D information to the technician modeling the part, saving them time by not searching for additional dimensions.

Step 6a: 3D Printing

3D printing can be performed for prototyping or verifying part fitment before machining expensive material. In some circumstances the 3D printed part can even serve as the duplicate replacement.

Step 6: Fabrication

Through a fully developed CAD model, drawings and CAD files are delivered to a machinist who determines the most cost effective and appropriate process for fabricating the part. Finally, cost savings are again realized when the part fits perfectly avoiding start over - remeasuring, and fabricating.

Benefits of 3D Laser Scanning

Versatile

Virtually limitless 3d scanning – no matter the part size, complexity, material or color

Metrology-Grade Measurements

Accuracy of up to 0.0012 in., resolution of up to 0.002 in., high repeatability and traceable certificate.

Standalone Device

No external positioning system, no arms, no tripod or fixture.

No Rigid Setup Required

The part and scanner can be moved freely during scanning. Take it from place to place or use it in-house or on site.

Automatic Mesh Output

Model generation, right as you complete acquisition for realtime visualization of what is scanned.