3D Scanning

What is 3D Laser Scanning?

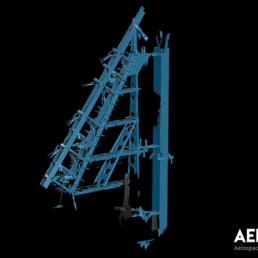

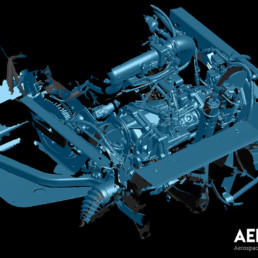

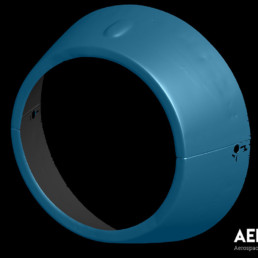

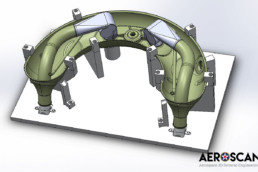

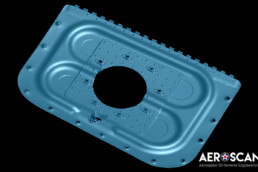

3D scanners are tri-dimensional measurement devices used to capture real-world objects or environments so that they can be remodeled or analyzed in the digital world. The latest generation of 3D scanners do not require contact with the physical object being captured. We utilize non-contact portable 3D laser scanners not only for their versatility but their speed.

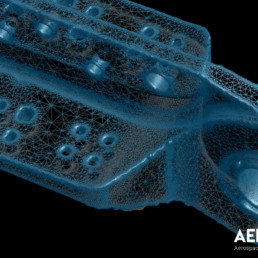

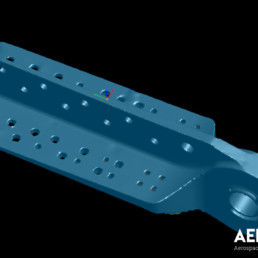

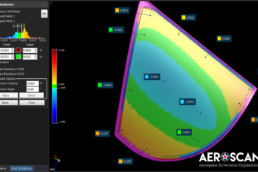

3D scanners can be used to get complete or partial 3D measurements of any physical object. The scanner produces a digital, high density mesh that measures more accurately when compared to traditional measurement devices (rulers, calipers, micrometers, etc.)

Aeroscan’s expertise allows us to leverage this scan data and apply it efficiently and effectively to aerospace reverse engineering or inspecting applications. Scanning objects in 3D is not difficult, however, knowing how apply that data to solve a problem is the expertise that we provide.

Bottom line – 3D scanning bridges the gap between existing objects in the real world and the digital environment that is the modern platform for engineering. The aerospace industry can directly benefit from this with a faster return to service, return to market, improved quality and even product performance.

Want to learn 3D scanning basics and the workflow after scanning? Visit our Solutions page where you can see illustrations.

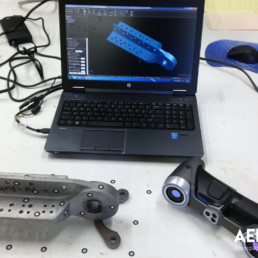

What type of a 3D scanner does Aeroscan use?

After experiences with other types of 3d scanners. Aeroscan determined that 3D scanning with a portable hand held laser scanner not only provides the most versatility but the accuracy necessary for the majority of aerospace applications. This type of laser scanning uses positioning targets placed on or around the subject to be scanned. The targets act as coordinated positions that allow the scanner to move around the object in any direction without the restrictions of an arm or fixed tripod. More importantly it does not limit the physical limit of the subject to be scanned. However, if the subject to be scanned requires high tolerances between distances over approximately 12’, the addition of photogrammetry needs to be incorporated. We are trained and can perform this additive service.

Scanner technical information:

- Resolution: 0.0020 in. (0.050 mm)

- Accuracy: Up to 0.0012 in. (0.030 mm)

- File format output: .dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr

- Measurement rate: 480,000 measurements/ sec.

For additional scanner details, visit the Engineer page.